Landstrasse 71

Kaiseraugst, 4303

Switzerland

Overview

Key Contact Personnel:

Norbert Maroldt, CEO n.maroldt@vogel-ag.net

Year Founded: 1970

Percent of Sales in Export Markets: 95%

Total Annual Sales: USD 5 to 10 million

Major Export Markets Served: Worldwide

Products

Production Machinery

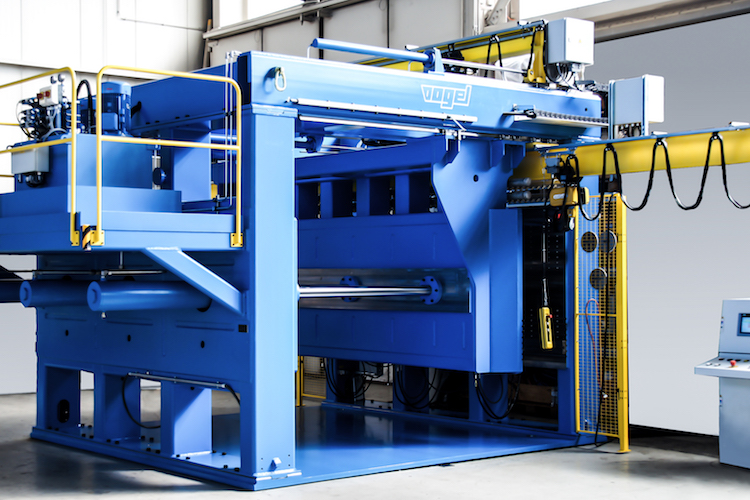

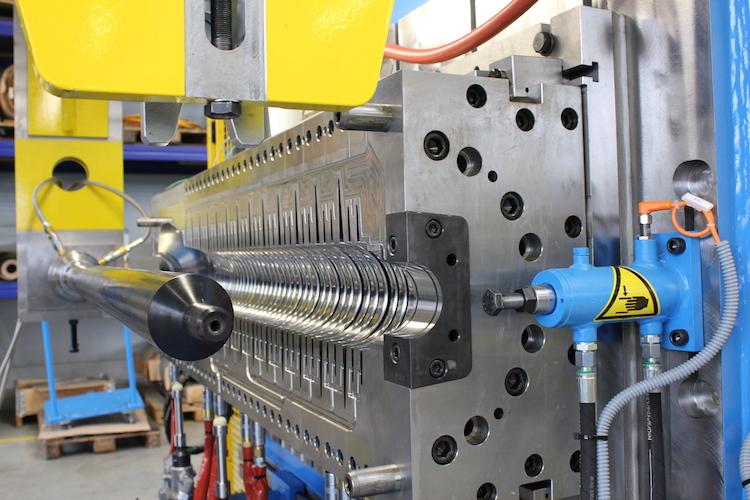

VOGEL has specialized in clamping units, moulds, mixing and dosing systems as well as customized equipment for the manufacturing of insulation parts made of epoxy resin and liquid silicone rubber (LSR) for the electrical and automotive industry.

Since the APG process was invented in the early 1970s, VOGEL has been demonstrating technical capability with view to the respective equipment, e.g. the first equipment for the automatic shielding of composite insulators with liquid silicone rubber (LSR).

Nowadays, the machines and systems by VOGEL moulds & machines AG are found at the highest technical level. Almost all large manufacturers of medium and high voltage equipment and suppliers of cable accessories worldwide are among the range of customers.

The latest developments in the field of e-mobility allow nowadays well-known German automobile manufacturers to produce rotors for e-drives in quantities of several thousands per day on VOGEL equipment with highest precision in a fully automatic vacuum pressure gelation process.

In the wind energy sector our highly developed mould design enables high quality vacuum casting of complex stators that are currently installed in the largest wind turbines in the world.

Locations

Location of Manufacturing Plants and Laboratories:

Greifenthaler Straße 28, Ehringshausen, Germany, 35630